What is Keder?

Kedar is a fast, easy, and secure mounting system for mounting temporary and permanent structures, clearspan structures, large-scale banners, signage and more. Keder was invented so long ago that no official inventor has ever been identified. The keder method has been used for many years to hoist a sail onto a mast and can be accomplished with very simple tools, materials, and techniques.

The term keder is derived from early European nomadic tribesmen, from whom we derive the Germanic word "köder." Many people have noticed the practicality of keders with modern materials and technology, and they are frequently used by those in the signage, fabric structure, and agricultural industries.

The History of Keder

The creation of keder dates so far back that an official inventor has never been identified. The keder method has been used to hoist a sail onto a mast for years and can be accomplished using very simple tools, materials and techniques. The term keder dates to early European nomadic tribesmen, to whom we own the derivation of the Germanic word “köder”.

With modern materials and technology, the practicality of keders has been noticed by many and is often used by those in the signage, fabric structure and agricultural industry. Keders are a highly customisable and robust option for signage or fabric structures, offering a long-term solution that is as quick to set up as it is to dismantle.

J & J Carter Keder Solutions

J & J Carter prides itself on offering the highest quality Keder products and accessories, servicing the Tenting, Printing & Marine Industries. The keder bead is slid through the length of the connecting rail, forming a basic attachment using the resistant force, that would pull the keder out laterally through the slot. Our products allow you to create sleek, strong, and polished finished products, providing the maximum impact with effortless installation.

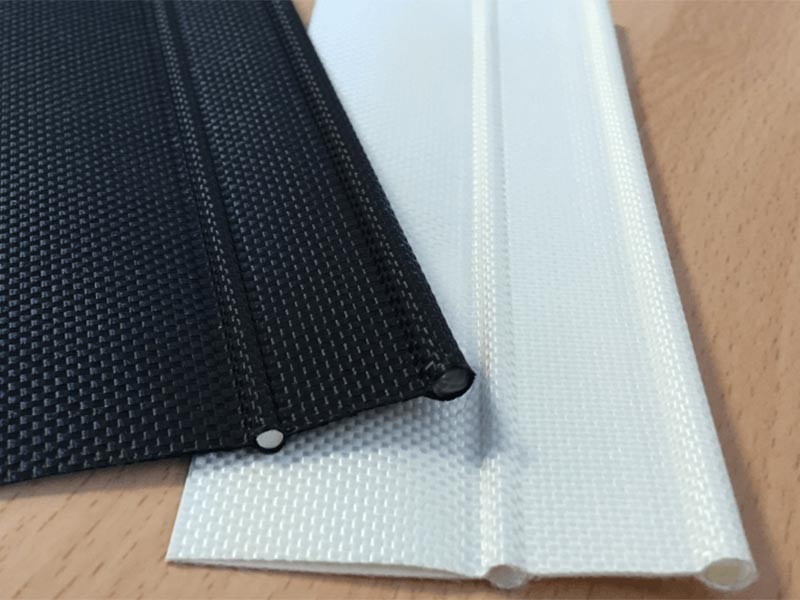

Our Keder is made from a core, generally PVC, with a slit PVC coated fabric wrapped around it. The process of fusing the two components is known as High Frequency or Radio Frequency Welding.

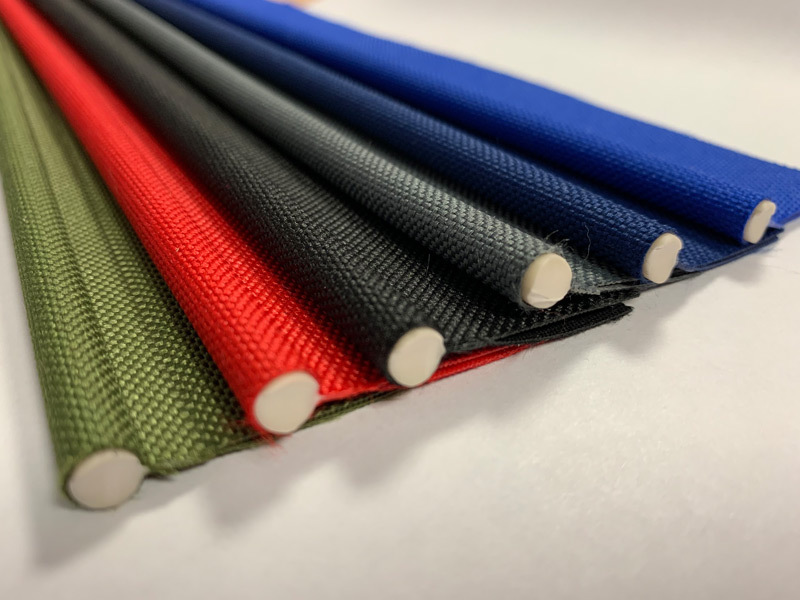

Coloured Keder

We now offer a range of Keder in new colours to suit a variety of applications:

- Awnings

- Furnishings

- Sprayhoods

- Banners

- Promo Tents

- Military Tents

Minimum order requirements for custom coloured cloth slitting are as follows:

- up to 9mm core - 1,800m

- 10mm to 12mm core - 1,500m

- 13mm core - 1,000m

Cloth Specification:

- Fabric 150gsm textured polyester, warp and weft with water resistant finish.

- Coating - 300gsm PVC coating, suitable for both stitching and high-frequency welding.

We can fabricate to order to suit your required specification. For more information on our Keder products contact our team today.